6 ELECTRICAL FAULT ZONES FOR MOTOR TEST

Troubleshooting an electric motor that is suspected to have an electrical problem should not result in the statement, “The motor is fine.” To confidently report the electrical condition of a motor and ensure that your recommendation is taken seriously, there are six areas of interest known as Fault Zones that must be looked at during the troubleshooting effort. Missing any of these zones could result in missing the problem and losing credibility in your troubleshooting skills.

Power Quality

Power Quality refers to the condition of the voltage and current signal. Mechanisms that can cause poor power quality include single and three phase non-linear loads, variable frequency drive units, starting and stopping of nearby equipment, voltage spikes, and more. These influences can cause excessive harmonics in the distribution system, which can result in overheating of the insulation system.

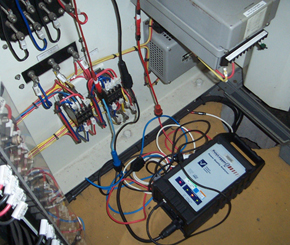

Power Circuit

The power circuit refers to all the conductors and connections that exist from the point at which the testing starts through to the connections at the motor. This can include circuit breakers, fuses, contactors, overloads, disconnects, and lug connections.

Insulation Condition

This refers to the insulation between the windings and ground. High temperatures, age, moisture, and dirt contamination all lead to shortened insulation life.

Stator Condition

When we mention the stator, we are referring to the DC or 3-phase AC windings, insulation between the turns of the winding, solder joints between the coils, and the stator core or laminations.

Rotor Condition

This refers to the rotor bars, the rotor laminations, and the end rings of the rotor, it is said 10% of motor failures are due to the rotor. The rotor, although a small percentage of the motor problems, can influence other fault zones to fail.

Air Gap

This relationship references the air gap between the rotor and stator. If this air gap is not evenly distributed around the 360 degrees of the motor, uneven magnetic fields can be produced. These magnetic imbalances can cause movement of the stator windings, resulting in winding failure, and electrically induced vibration, resulting in bearing failure.

Conclusion

In conclusion, the term “The motor is fine” is just not enough to ensure that we are taken seriously and that a true assessment of a motor’s health has been performed. If the decision is up to you as to what to do in a troubleshooting or diagnostic situation, look at the whole picture. If at all possible, do not make a quick decision. Break the system down into its individual fault zones, test each fault zone completely with every technology available to you, and finally make your recommendations, written or verbal, using the terminology used in fault zone analysis to express your confidence and capabilities.

For additional technical support, please contact us, Mega Link Co.Tz